Material Testing Services

United Controls International (UCI) is capable of performing the following tests under our ISO 9001 and/or our NQA-1 program to meet our customer’s requirements. Our labs are staffed with highly qualified and experienced testing personnel who are committed to upholding the utmost quality standards in all of their practices. UCI can identify / verify the properties of all metallic and non-metallic materials. Common tests that UCI performs are shown below, please contact us if you require a test that is not listed.

Material Testing Capabilities

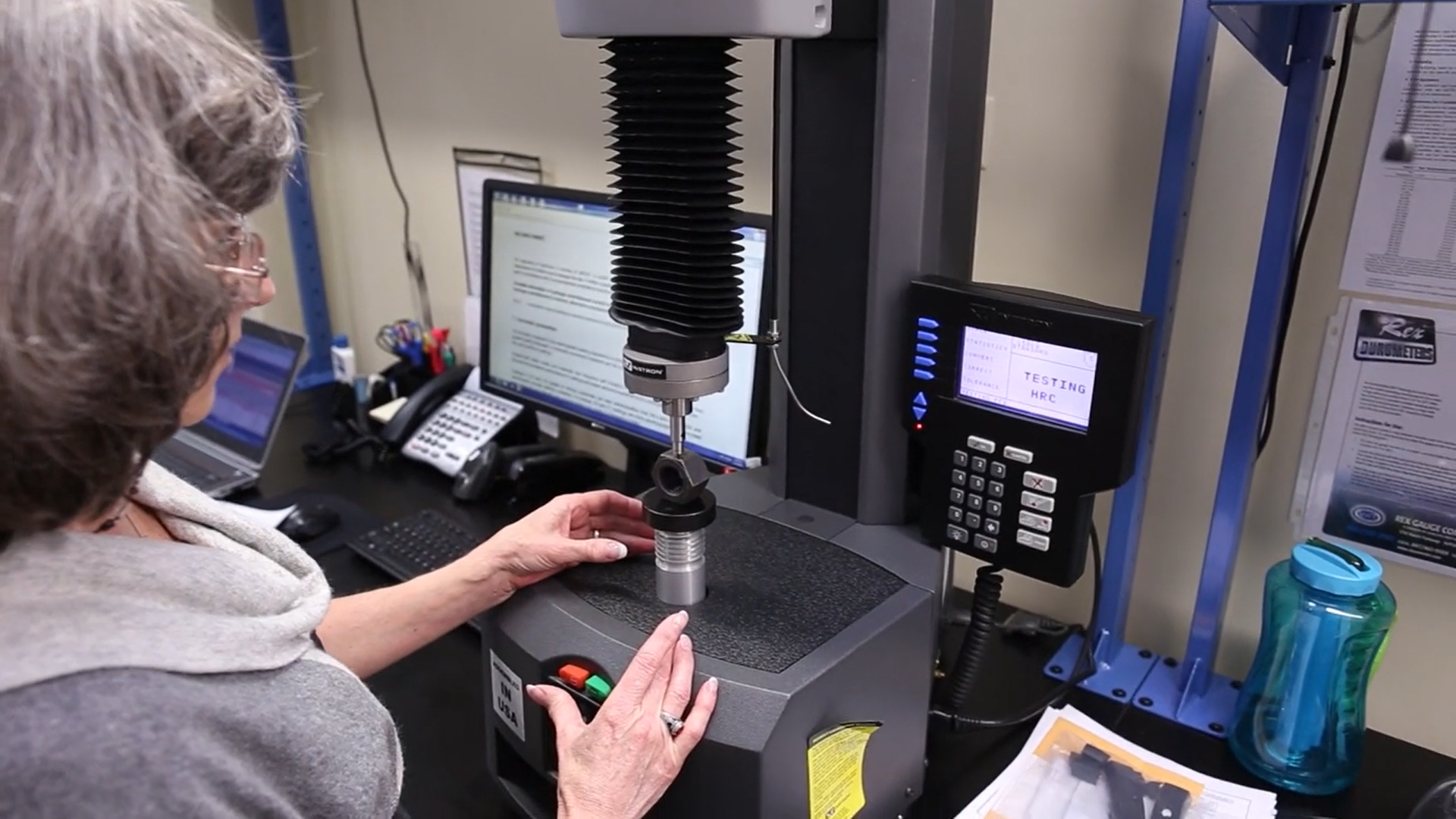

- Hardness Testing

- Durometer Testing

- Carbon / Sulfur Analysis (LECO)

- Fourier Transform-Infrared Spectroscopy (FTIR)

- Optical Emission Spectroscopy (OES)

- X-Ray Fluorescence (XRF)

Hardware / Fastener Testing

- Tensile Strength

- Yield Strength

- Elongation

- Resilience

- Proof Load

- Wedge Testing

Oil, Grease, Lubricant, and Solvent Testing

- Dropping Point

- Penetration

- Flash Point

- Viscosity

Gases and Refrigerant Testing

- Purity

- Specific Density

- Moisture Content

- Rockwell Hardness

-

The Rockwell hardness test method, as defined in ASTM E18, is the most commonly used test method for testing metal parts. This test is considered to be destructive when performed on samples requiring pretest preparation. There are several different Rockwell scales each denoted by a single additional letter such as HRA, HRB, HRC, HRF and superficial scales such as 15N, 30N, 45N, 15T, 30T, 45T. The Rockwell test method can be used on all metals except in situations where the test metal structure or the surface conditions of the test specimen could introduce excessive variations.

- Microhardness

-

Microhardness is a testing method used to determine the material hardness and/or resistance to penetration on very small or thin samples. This method also helps with measuring small regions of composite samples as well as plating hardness. Precise information about the surfaces of various microstructures can be quantified using this method. Microhardness tests can also be used to measure surface to core hardness on carburized or case-hardened parts (case depths). UCI has the capability to perform both Vickers and Knoop Microhardness. The Microhardness test method can be used on all types of metals.

- Brinell Hardness

-

This test method, as defined in ASTM E10, is most commonly used to determine the Brinell hardness of items that have a structure that is either too coarse or too rough to be tested using other test methods. Types of items that would use this test method are cast iron parts, large steel frameworks, and aluminum samples.

- Durometer Hardness

-

Durometer hardness testing is used to determine the hardness of thermoplastic elastomers, vulcanized rubber, elastomeric materials, cellular materials, gel-like materials, and other plastics that are unsuitable for measurement through the conventional Rockwell or Microhardness testing. Hardness, when measured on a Shore A or D scale, is a material's resistance to surface penetration.

- Carbon / Sulfur Analysis via LECO

-

Carbon / Sulfur Analysis is a Combustion Infrared Detection Technique used to determine carbon and sulfur content within metallic components. A sample is accurately weighed and placed in a ceramic crucible. The crucible is placed in a high temperature furnace and burned in a stream of oxygen. As a result, CO, CO2, and SO2 are formed as outputs from the combustion of the carbon and sulfur in the sample. An infrared absorption detector is then used to measure the absorption of the infrared wavelengths characteristic to CO2 and SO2. At these wavelengths, the amount of infrared absorption correlates to a quantitative content based on standards and weight of the original sample. Types of material which can be tested using LECO are bars, plates, sheets, fasteners, etc.

- Fourier Transform-Infrared Spectroscopy (FTIR)

-

FTIR is an analytical technique used to identify organic material and inorganic additives. This technique measures the radiation from both absorption and transmission to create a molecular fingerprint of the sample. The molecular fingerprint is then compared against a known spectrum, generated by pure materials, in order to determine the material composition. Types of material which can be tested using FTIR are rubbers, plastics, oil, grease, fiberglass, coatings, etc.

- Optical Emission Spectroscopy (OES)

-

OES is an analytical technique used to determine the elemental composition of a broad range of metals, alloy identification, and quality control. The most ideal method is the measuring principal of the spark excitation. This method provides the perfect instrumentation for metal analysis in different industrial applications and environments including the nuclear industry. Types of samples which can be tested using OES are bars, plates, sheets, fasteners, etc.

- X-Ray Fluorescence (XRF)

-

XRF is a non-destructive analytical technique used to determine the elemental composition of materials. The XRF analyzer determines the chemistry of a sample by measuring the fluorescent (or secondary) X-ray emitted from a sample when it becomes excited by a primary X-ray source.