Repair and Refurbishment

Circuit Breakers

UCI has extensive experience in refurbishing, reworking, and dedicating large legacy circuit breakers. The process involves an evaluation of the circuit breaker, determination of what parts need replacement, development of a repair/refurbishment plan, procurement and dedication of the new replacement parts, re-assembly, and final testing and dedication of the newly refurbished circuit breaker. UCI will provide Engineering Evaluations for the replaced components that are found to be not like-for-like replacements.

Motors

At United Controls our Motor Specialists readily dedicate and qualify new motors as well as test, refurbish, and repair small, medium, and large motors for use in nuclear safety-related and non-safety applications.

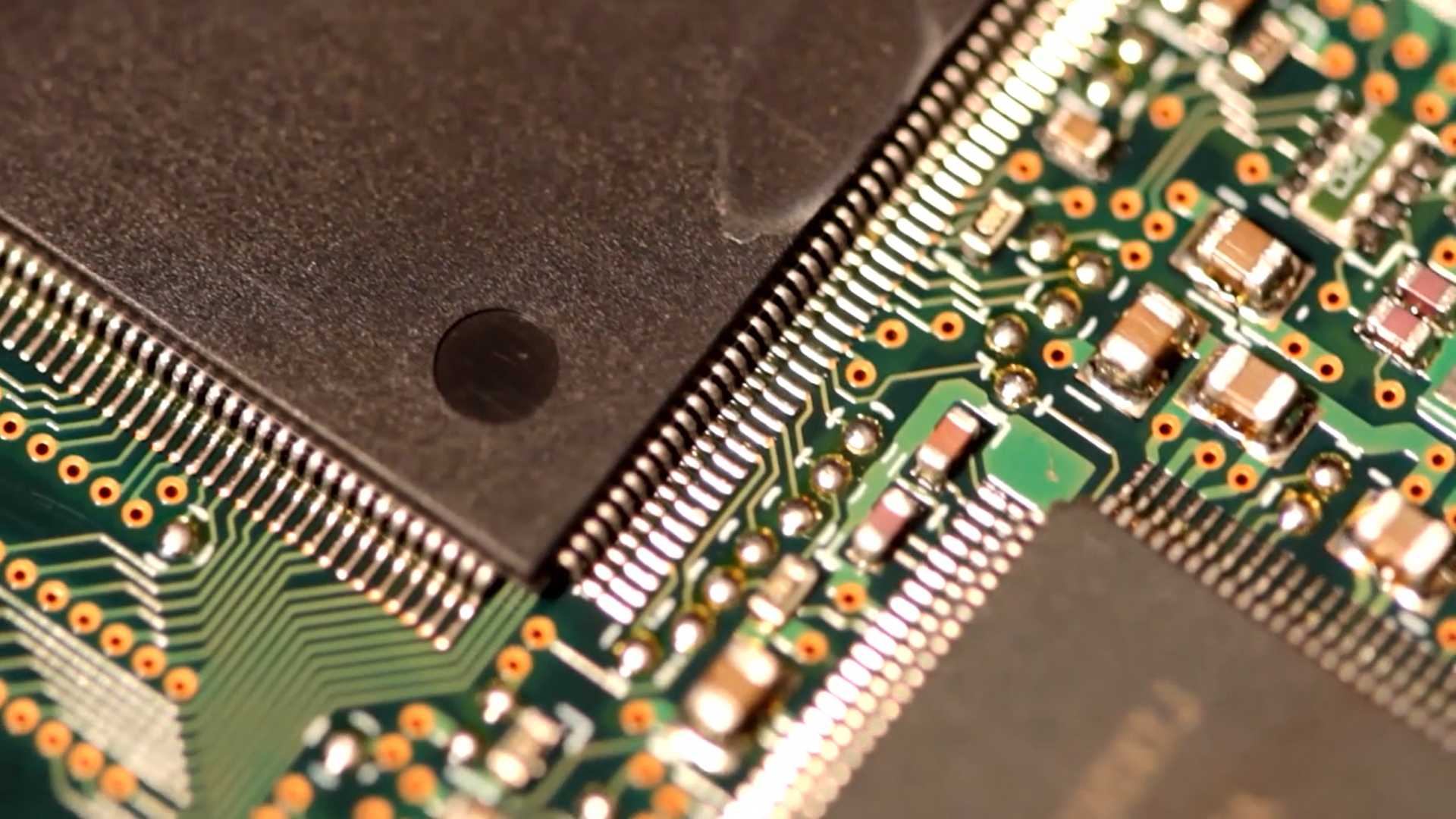

Electronic Equipment

Contact UCI for a complete repair or refurbishment of your obsolete or hard to find electronic equipment. UCI’s engineering department will evaluate the item and perform a failure analysis and/or evaluate the item for aged components. The team will then provide Engineering Evaluations for the replaced components that are found to be not like-for-like replacements. Last, Burn-in testing will be performed to verify that there is no infant mortality in the replaced components.